01

Best Price

Get competitive pricing without compromising on quality. We ensure you receive the highest value for your investment, every single time.

02

Expert Guidance

Our specialists offer daily insights and professional advice, helping you choose the perfect solutions tailored to your unique requirements.

03

One Stop Solution

From concept to delivery, we handle everything under one roof, offering you a seamless, hassle-free experience.

Precision Machines.

Reliable Results.

At BSM India, we design and manufacture high-performance footwear making machines that bring precision, speed, and reliability to your production floor. Whether you’re crafting handcrafted leather shoes or managing a high-volume sports shoe line, our machines are engineered to deliver consistent results, shift after shift.

From automatic sole attaching systems to rotary cementing units and hydraulic cutting presses, each machine is built using industrial-grade components, advanced automation, and rugged construction — designed to meet the evolving needs of modern shoemaking.

40 +

Experience

98 %

Client Retention

300 ᵏ

Global Installations

24/7

Technical Support

Getting Started With BSM

01

Choose Your Product

Select from our extensive range of advanced footwear machinery to suit your business needs.

02

Free Consultation

Get expert guidance from our team to help you choose the perfect machinery for your production requirements.

03

Get Your Quotation

Receive a customized quotation based on your selected machines and project scale.

04

Delivery & Installation

We ensure safe delivery and professional installation, so your machines are ready to perform from day one.

Explore Our Products

As a trusted Footwear Making Machine Manufacturer, BSM India delivers advanced and customizable machinery solutions across a diverse range of industries. Our machines are designed for precision, durability, and efficiency—empowering manufacturers to enhance productivity and product quality.

-

Cover Type Sole Press (pneumatic)

Model No. BS-2003 Power 220V 50Hz Air Pressure 6-7 KG/cm² Compression Time 8-10 s Efficiency 180 pair/hour Outline Dimensions 440 × 780 × 1130 mm Weight 75 kg -

Glass jar Applicator [for Rubber based Adhesives]

Model No. BS-003 Power 220V 50Hz Motor Power 180 W (1/6 hp) Roller Width 150 mm Outline Dimensions 425 x 375 x 440 mm Weight 32 Kg -

Swing Arm Cutting Press

Model No. BS-200 Max. Cutting Force 22 Ton Area of Work Table 900 x 430mm Cutting Area 370 x 490mm Motor Power 750W Machine Dimensions 900 x 820 x 1400mm Packing Size 1050 x 1000 x 1500mm Weight 740Kg -

Counter Moulding Machine (Hot & Cold)

Model No. BS-516 Dimension 890 x 1480 x 2000mm Weight 600 Kg Voltage 220V/50HZ Power 2.7 kW Air Pressure 0.6 Mpa Capacity (Pairs/8hr) 1500 -

TPU Fusing Machine

Model No. BS-605 Voltage AC380V/50HZ Power 20KW 3 Phase Running Load 12-13 Kw Air Pressure 0.5 MPA Chiller Capacity 2 Ton Temperature Accuracy +3°C Plate Pressure 12 Ton (Double Pressure) Working Area 406 x 609 mm Fusing Time 8-30 Second (Depends On The Type of Material) Heating Plate Top & Bottom Heating Cooling Plate Top & Bottom Cooling Machine Size (mm) 2000 x 1930 x 863 mm Net Weight 1450 kg -

Hydraulic 4 – Column Beam Cutting Press

Machine Specifications – Model No. BS-750 Maximum Cutting Force 400 KN (40 Ton) Tension Distance 60-160 mm Area of Work Table 1600 x 580 mm Stroke Adjusting Range 5-100 Motor Power 2.2 KW Weight (Approx.) 2000 KG Oil Tank Capacity 60 Ltrs -

High Frequency Welding Embossing Machine (hydraulic)

Machine Specifications – Model No. BS-602 Power 8 KW Voltage 220V or 380V Input Power 8.5 KVA Frequency 27.12 or 40.68 MHz Maximum Electrode Spacing 160-220 mm Working Table 350 x 700 mm or 400 x 700 mm Temperature Control Range 50-300°C Adjustable Welding Time 0-10s Adjustable Table Size 1070 x 1210 mm Oil Hydraulic 68no Oil Capacity 30 Ltr. Dimension 1070 x 1680 x 1560 mm Machine Weight 320 KG

Ready to Upgrade Your Footwear Line?

Take the first step toward smarter, faster, and more efficient production. Let’s find the right footwear making machine for your business.

Tailored for Your Production Line

At BSM India, we understand that every footwear manufacturer faces unique challenges — from space constraints and skilled labor availability to production volume and budget. That’s why our range of footwear making machines is designed to adapt to your environment, your team, and your goals.

Whether you’re just launching your brand or managing a high-output facility, we offer purpose-built solutions that scale with your needs, without compromise on quality or durability.

Startups & Niche Brands

Smaller teams. Limited space. High-quality expectations.

Our compact and affordable machines help startups produce with precision — without overinvesting in oversized systems.

Our first BSM machine fit into a 300 sq. ft. workshop — and we shipped our first 500-pair order within a month.

Sports & Casual Footwear Manufacturers

Mid- to high-volume manufacturers need speed and consistency. Our machines are built for both — with digital controls, automated cycles, and smooth material handling.

BSM’s sole attaching machine helped us cut labor costs by 40% while doubling production.

Industrial & Safety Shoe Producers

Heavy-duty shoes need heavy-duty machinery. From steel-toe soles to abrasion-resistant uppers, our machines are engineered to handle tough jobs, day after day.

We manufacture ISI-marked safety boots, and BSM’s hydraulic cutting press was a game-changer.

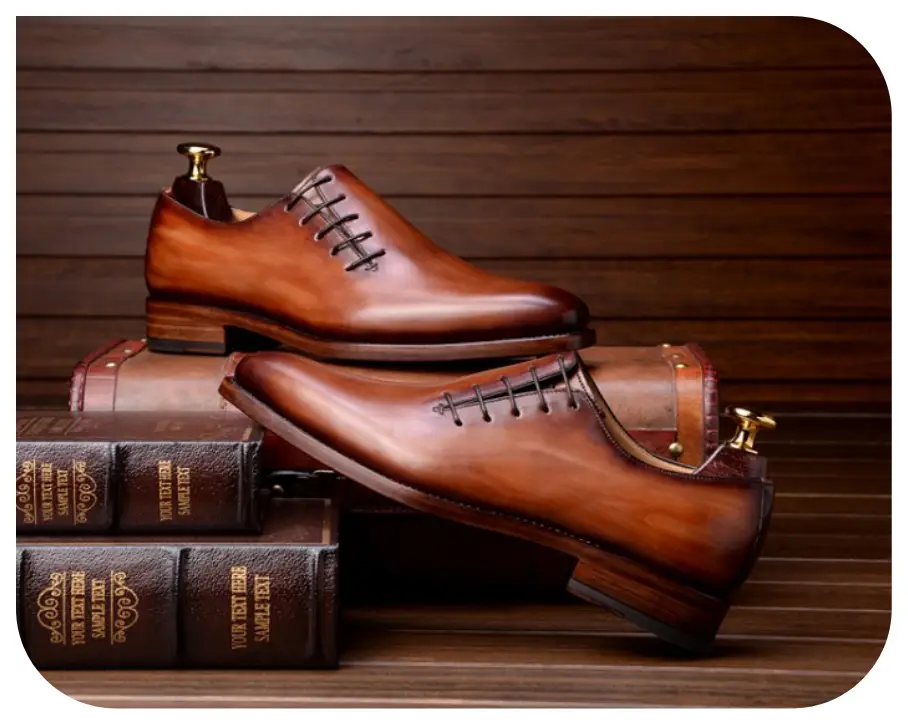

Fashion & Premium Footwear Brands

Luxury requires detail. Our footwear making machines ensure every stitch, press, and bond is clean, consistent, and showroom-ready.

The finish we get with BSM’s rotary cementing machine rivals imported machines — at half the cost.

Customization That Works with You

Every factory layout is different. Every team works differently. That’s why we go beyond the box:

We work closely with your production manager or plant head to ensure your new footwear making machine is not just installed — it’s integrated into your workflow.

Want us to recommend the perfect setup for your factory size and output goals?

Why Leading Footwear Making Machine BSM India

Choosing the right machinery partner can make or break your production efficiency, product quality, and long-term profitability. At BSM India, we go beyond delivering hardware — we provide you with a reliable foundation for growth.

Thousands of manufacturers — from local startups to global exporters — rely on our footwear making machines because of our reputation for delivering consistent performance, responsive service, and unmatched value.

Over a Decade of Footwear Machinery Innovation

With 10+ years of industry experience, BSM India has played a key role in advancing how footwear is made. From manual to semi-automatic to fully automated systems, we continuously improve our machines based on factory feedback and global trends in shoemaking.

400+ Operational Units Across India & South Asia

Our machines are already working 2–3 shifts per day in production units across:

Wherever shoes are being made, you’ll find BSM footwear making machines delivering high-quality results.

Field-Tested Technology, Built for Factory Realities

We don’t believe in “lab-only” prototypes. All BSM machines are developed, stress-tested, and field-hardened in real production environments before being released to the market.

Responsive After-Sales Support

Downtime kills productivity. That’s why we’ve built a national network of trained engineers, with rapid service response and ongoing technical support.

“BSM’s support team is just a call away — even in peak season. That peace of mind is priceless.”— Leading Footwear Manufacturer, Bahadurgarh

Customization That Works with Your Factory

Your production line is unique — and your machines should be too. BSM India offers flexible customization options based on your materials, shoe types, and layout constraints.

Proven ROI for Manufacturers

We focus on delivering machines that pay for themselves quickly by boosting productivity and minimizing wastage. Our clients consistently report faster payback periods and improved profitability after installation.

Clientele

At BSM India, a trusted Footwear Making Machine Manufacturer, we take pride in partnering with some of the world’s leading footwear and fashion brands. Our high-capacity shoe machinery is known for its efficiency, ease of operation, and low maintenance—making it ideal for producing sports shoes, canvas shoes, casual footwear, and more.

What Our Client Say's about us

Get Every Updates!

Take the first step toward smarter, faster, and more efficient production. Let’s find the right footwear making machine for your business.

Do You Have Any Questions!

Frequently Asked Questions

Energy efficiency is a key design focus for us. Our machines incorporate advanced hydraulic and electrical systems to minimize power consumption, reduce operating costs, and meet environmental standards.

As a quality-driven Footwear Making Machine Manufacturer, each machine undergoes stringent quality control tests, including performance trials and durability checks, before it reaches your facility to guarantee reliable and consistent operation.

Yes, BSM India designs its footwear machines to be compatible with existing manufacturing systems and workflows, enabling seamless integration and minimal disruption during upgrades or expansion.

We provide comprehensive manufacturer warranties covering parts and workmanship. Extended warranty packages and maintenance contracts are also available to ensure long-term protection and peace of mind.

Yes, operator training is an integral part of our service. As an experienced Footwear Making Machine Manufacturer, we conduct on-site training sessions to equip your staff with the knowledge to operate and maintain the machines safely and efficiently.

Our machines cater to a wide range of production scales—from small and medium enterprises to large industrial manufacturers. We design machines capable of high-speed, continuous operation to meet demanding output requirements.

Absolutely! We welcome visits to our manufacturing facility, where you can witness live demonstrations, explore machine features firsthand, and discuss your specific production needs with our expert team.